Saving time and money with value-add deployment of 3D data

-

What area of your project can be streamlined with use of 3D data?

-

What can we do onshore that might save us having to go offshore?

-

How can we engage our stakeholders and share a truly collaborative view?

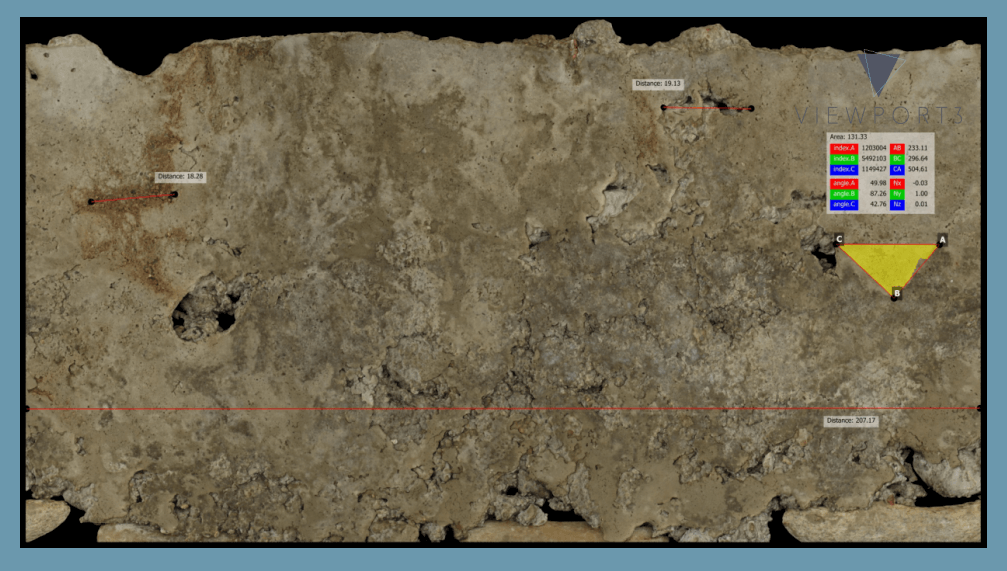

Let’s start with an image. Below you will see a mock-up of a core sample. Following 3d photogrammetric scanning, we have been able to ‘unroll’ the geometry and verify an accuracy level of 0.52mm;

Scanning of real life geometry

3D scanning is an extremely powerful tool. In our opinion the value isn’t in putting your face on a lego figure, and it’s not for people either, (unless you’re about to star in a video-game).

We see the technology quite differently;

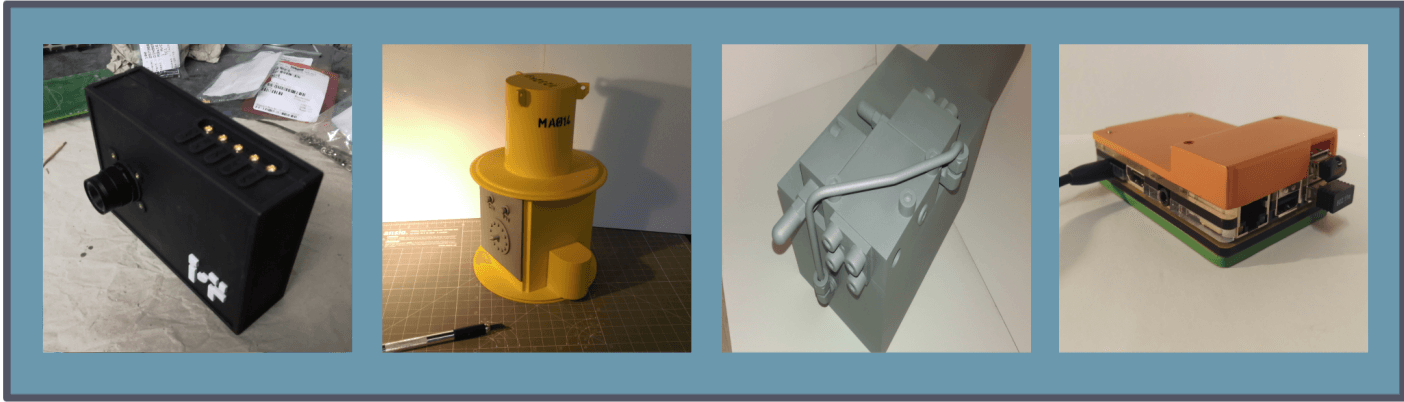

- Dimensional control of crucial equipment

- Dimensional reports of damage found during survey

- Conversion of images and video into highly accurate 3D geometry

Reverse Engineering from ‘as-is’ data

Once your data is obtained, you are free to manipulate and interrogate the data as the project demands. Compare it to as-built data, or the previous scan. Highlight and inspect anomalies. No budget for a new survey? No problem, just send in your latest survey images or video.

- Accurate comparison of scan data with legacy CAD, as-built or as-is records

- “Deviation map” visualisations showing location and extremity of anomalies and deviations beyond as built or previous scan

- Point clouds as a basis for FEA analysis

Physical technical modelling

Your data can also be prepared for creation as a real life physical object via 3d printing. Where a recovery meeting is arranged to discuss your challenge, be sure to invite the problem part. Collaborate with a shared view of the issue to add value to the project.

- Improve understanding with non-technical stakeholders

- Exhibit and explain your product or concept

- Share a collaborative view with your colleagues and customers

We’d be glad to answer your questions. Feel free to contact us at Viewport3

Thanks for reading